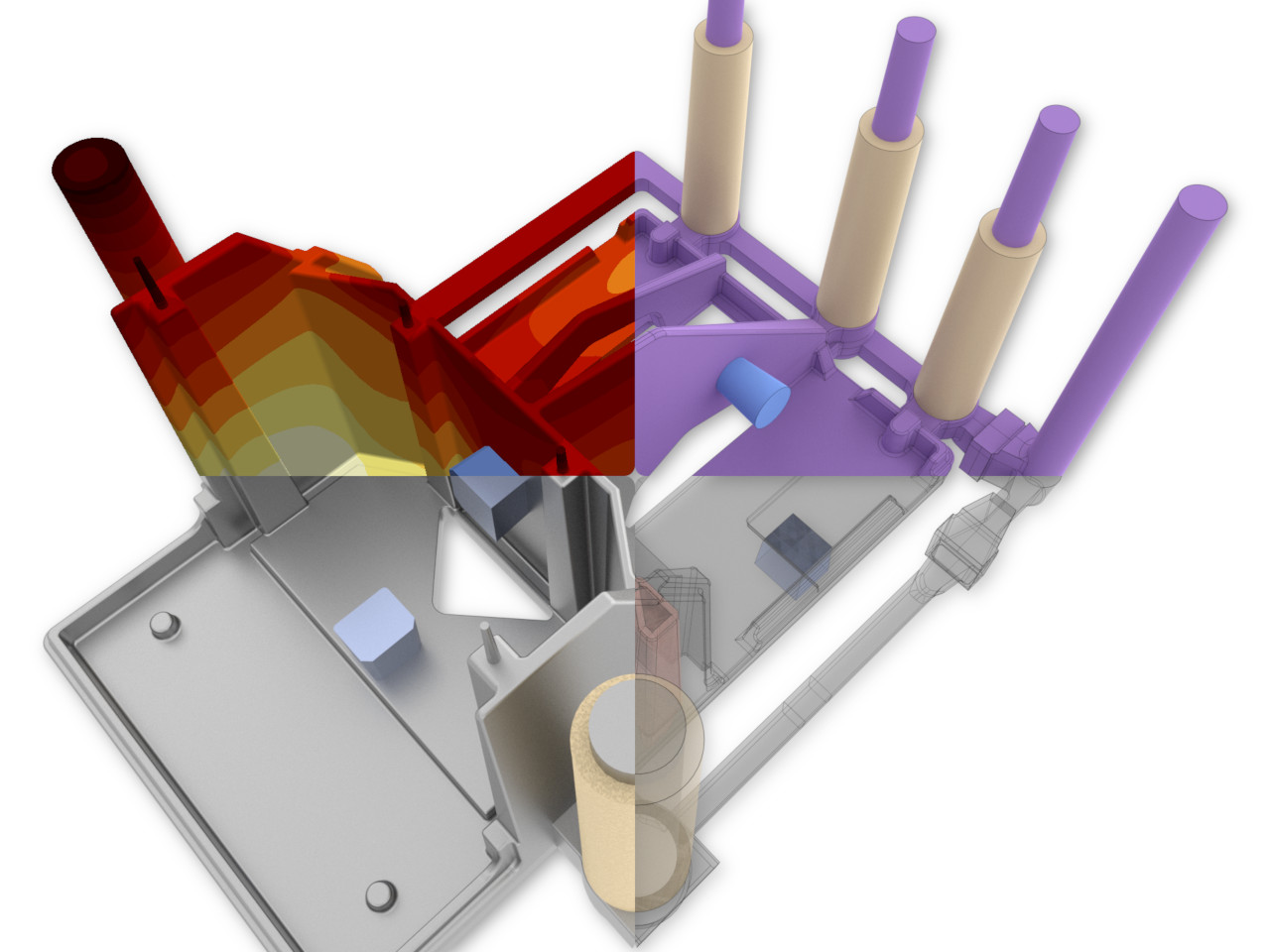

In today's casting processes, a wide variety of thermally effective devices are used, from insulating or exothermic feeder sleeves and thermoelectric heaters to water cooling pipes and contour chills. It is not possible to reliably predict the influence of these techniques on the solidification process using a purely geometric method. However, in order to not only identify potential problem areas in the course of process planning, but also to validate technical solutions as early as possible, Visiometa also includes a flexibly configurable thermal solidification simulation.

In contrast to the simplified modulus analysis, the user can now define the thermophysical properties of casting and molding materials together with other process parameters. The results are automatically calibrated by means of a comparative calculation to obtain a process-neutral modulus value. Despite the inherent complexity, great care was taken during development to maintain the ease-of-use and rapid workflow that is characteristic of Visiometa.

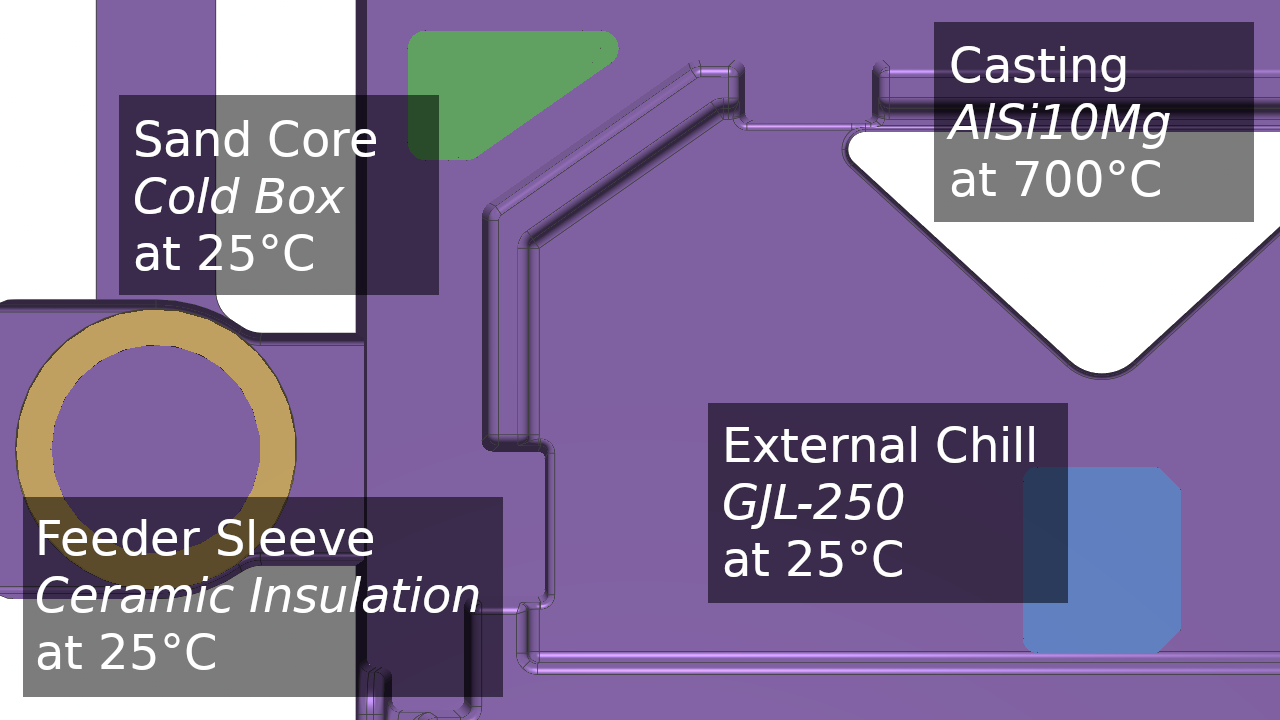

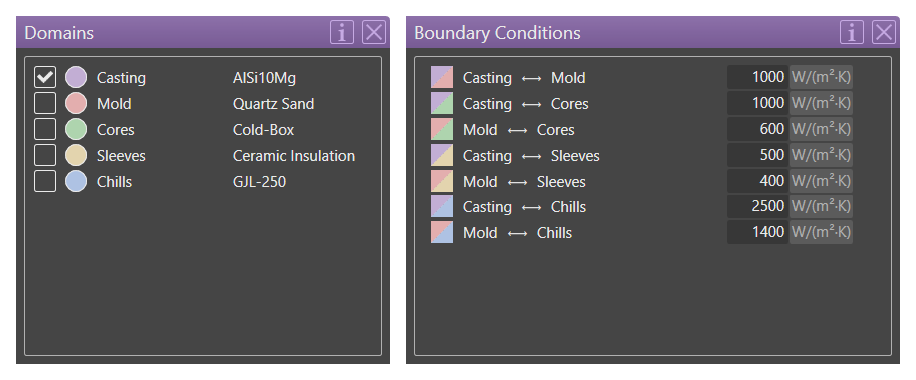

The simulation space is first discretized and broken down into so-called domains. Each domain is then assigned a specific material with individual properties and thermal effects. Where different domains meet at a contact surface, special boundary conditions are generated, that serve to model the actual heat transfer.

When solving partial differential equations, as they typically occur in heat conduction problems, large linear equation systems with many millions of unknowns arise. In order to perform these very extensive calculations in a time-efficient manner, software developers today rely primarily on parallelization and special numerical algorithms. Since virtually all modern computer processors are divided into several computational units called cores, the general rule of thumb is that the more cores are available, the faster the solution can be found. In many commercial simulation programs, the use of multiple processor cores is therefore licensed separately, which means that the technical possibilities are often not fully exploited due to the high costs.

With Visiometa, the degree of parallelization depends only on the user's hardware, since no artificial restrictions are imposed. Most importantly, Visiometa can leverage the resources of dedicated graphics cards to increase performance even further, as most modern GPUs are much better suited for solving scientific problems thanks to specialized compute cores and a much higher degree of parallelization.